The EPS Innovation Timeline highlights the key developments and advancements in Expanded Polystyrene technology over time. From its early adoption as a lightweight, insulating material to its modern applications in sustainable packaging, construction, and engineering, EPS has evolved through continuous innovation. This timeline showcases the milestones that have shaped EPS into a versatile and essential material across multiple industries.

In 1949, Fritz Stastny, a chemical engineer at BASF, developed a pre-expanded polystyrene bead. BASF started the production of expandable polystyrene (EPS) in 1951

In the late 1950s, EPS began to be used in the automotive industry for seat foams, interior panels and other fill requirements.

In the 1950s, EPS started to be widely used in life jackets and other flotation devices. Before that, life jackets primarily used materials like cork or kapok. EPS gained popularity due to its light weight and buoyancy nature, making it suitable for various flotation applications.

Since the 1950s and up to the current day, EPS has been used to make film and theatre sets. Its lightweight nature and the fact it can easily be cut, sanded, painted and glued mean that it is extensively used in the creative industries.

By 1952, EPS was introduced at the Düsseldorf plastics trade show, setting the stage for its widespread use.

In 1955, the first flat roofs were insulated with EPS. The tightly sealed panel joints with no signs of shrinkage or deformation and its long-term durability made it ideal for this application.

Mass production of EPS starts in Brazil and France.

In 1957, the first ETICS was installed with EPS insulation and is still saving energy to this day.

EPS is a widely used packaging material, offering excellent protection during transportation. It provides thermal insulation for temperature-sensitive goods such as fresh produce, while also delivering robust cushioning for heavy items like household appliances.

EPS was first used in child car seats in the 1960s, with the use widening in the 1980s and continuing today.

In the 1960s, EPS fish boxes revolutionized cold chain logistics by providing lightweight, insulating packaging that kept seafood fresh during long-distance transport.

In 1962, EPS was chosen to transport the Mona Lisa thanks to its outstanding protective qualities.

In 1968 the first North American patent introduced the use of polystyrene in ICFs (insulated concrete forms) for use in the construction of dwellings.

In the 1970s, EPS beehives, often called ‘poly hives’ was first used in Europe. Today, they are widely used, with 99% of new hives in Denmark made from EPS and they are widely used in other Northern European countries.

EPS was introduced as an insulating core in steel and composite exterior doors to meet rising energy efficiency demands. By the 1980s–1990s, it saw widespread use in garage, entry, and cold storage doors due to its lightweight and effective thermal insulation.

In 1975 a patent was issued for a cycle helmet with a hard shell and a shock-resistant liner made of EPS. This marked a significant advancement in helmet design, as previous helmets relied on softer, less protective liners.

BASF patent an innovation – a grey EPS containing graphite to give an improved thermal performance and enabling the use of thinner insulation boards.

EPS was showcased in a uniquely designed chair giveaway. The project emphasized EPS’s lightness, mouldability, and sustainable potential for consumer products. By framing the giveaway as both a promotional and design experiment, EPS highlighted how everyday objects can serve as innovative vehicles for material storytelling and community engagement.

EPS takes center stage in the design world with the ‘Teacup’ project, a sculptural installation highlighting the material’s versatility, lightness, and formability. Developed as part of a creative architectural collaboration, the teacup demonstrates how EPS can be used beyond traditional packaging or insulation – embracing artistic expression.

In 2012 MegaTech Projects Ltd gained Network Rail approval for an innovative new system that uses EPS for platform extensions, new train stations, platforms in areas of flooding and other similar applications.

Synthos becomes the largest manufacturer of EPS in Europe.

At the end of 2018, BASF first used pyrolysis oil derived from plastic waste as a feedstock in its EPS production.

In 2020, the insulating properties of EPS became crucial for transporting COVID-19 vaccines globally, playing a big role in saving lives

On 16 June 2021 The PolystyreneLoop Recycling Plant opened in Terneuzen, Netherlands.

All EPS manufacturers in Europe produce a raw material that includes recycled content.

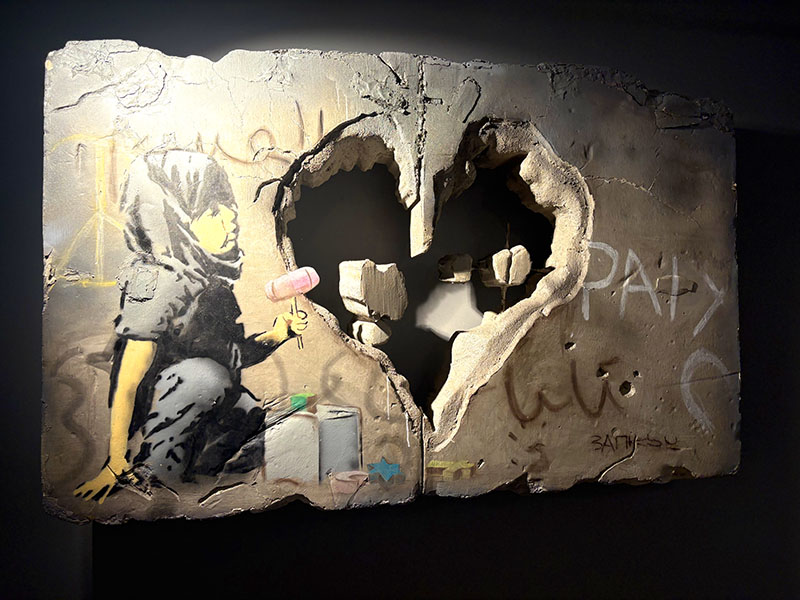

Banksy Goes EPS: Banksy’s Limitless installation used giant sculpted EPS blocks to pull off its dramatic design – proof that EPS isn’t just practical, it’s street-art ready.